Pallets and Skids in Transportation: Differentiation and Application

When it comes to logistics and warehousing, the terms pallet and skid are often used interchangeably, leading to confusion, which affects transportation efficiency, cost management, and inventory handling. This blog post will address common pain points associated with these two platforms, clarify their definitions, and guide companies on when to use them.

Table of Contents

Can't tell the difference between pallets and skids?

Many business owners and e-commerce sellers are often unclear about the specific differences and applicable scenarios between pallets and skids when arranging cargo transportation, resulting in bottlenecks in warehousing management and transportation efficiency. So, what is the difference between pallets and skids? What role do they each play in logistics and warehousing?

What is a pallet in warehousing logistics?

A pallet is a flat structure, usually made of wood, plastic or metal, used to carry goods, facilitate handling and stacking by mechanical equipment such as forklifts, and support goods during storage and transportation. It is mainly used for the overall transportation, loading and unloading of goods. Pallets have standardized dimensions and structures, which facilitate seamless integration in different logistics links.

It generally has the following features and advantages:

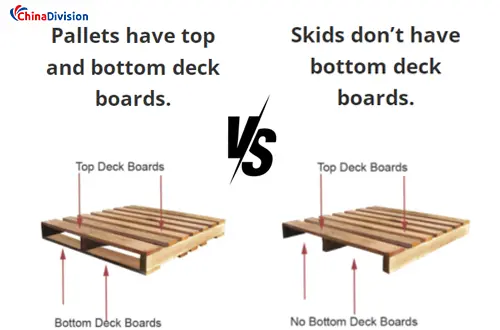

Double-layer design: Pallets have a top and bottom layer, which can provide enhanced stability and support for heavier loads.

Standard size: The most common pallet size is 48 x 40 inches (1200 x 1000 mm), which fits most warehouse racking systems and is ideal for stacking and storage in warehouses.

Forklift accessibility: Pallets are designed with longitudinal beams or blocks so that forklifts can easily lift and move them.

High stability: Pallets have two decks, upper and lower, providing better stability and load-bearing capacity.

Easy to stack: The bottom deck makes pallets easier to stack and store.

Suitable for heavy goods: Pallets can carry up to 1000 kg.

Pallets are ideal for stacking goods and are widely used in the logistics field for efficient storage and transportation.

Pallets also have disadvantages

Poor mobility: Pallets are not easy to tow due to the presence of the bottom deck.

Higher cost: Pallets use more materials, so they are heavier and more expensive than skids.

What are the types of pallets?

Wooden pallets: durable and economical, often used to carry heavy objects. It is the most common type of pallet, relatively cheap, but susceptible to moisture and rot.

Plastic pallets: lightweight, moisture-proof, ideal for food and medicine. It has the advantages of corrosion resistance, high temperature resistance, and easy cleaning.

Metal pallets: strong and durable, suitable for heavy goods, but the highest cost.

Shelvable pallets: designed for storage on pallet racking systems to maximize the use of vertical space.

According to the structure, it can be divided into flat pallets, grid pallets, column pallets, etc. Different types of pallets are suitable for different cargo characteristics and transportation needs.

What is a skid in warehousing?

Skids are similar to pallets, but usually do not have a bottom deck, so they are a simpler platform. The structure is relatively simple and the size is not uniform. Skids are mostly made of wood and come in a variety of shapes. They can be customized according to the size and shape of the cargo.

It has the following distinctive features:

Single-layer design: Skids have only one top layer, supported by the feet or runners below, and no bottom layer.

Low cost: Since there is no bottom deck, skids use less material, so they are lighter and less expensive.

Less Stability: Skids are generally less stable than pallets due to the lack of a bottom deck, which reduces friction, making them primarily useful for heavy machinery or equipment that require a minimum height.

Ease of Movement: Due to their design, skids can be dragged across surfaces more easily than pallets, which gives them an advantage in certain situations.

Skids are often used to carry heavier loads and are easier to move in certain applications. They provide a stable base for items, but their design limits some of the capabilities of standard pallets.

Disadvantages of Skids:

Less Stability: The lack of a bottom deck makes skids less stable than pallets.

Limited Weight Capacity: Skids cannot carry heavy loads like pallets.

Key Differences Between Pallets and Skids

Construction

Pallets have a more complex design, with a top and bottom layer, while skids are typically made up of a single platform.

Use Cases

Pallets are versatile and used across a wide range of industries, while skids are more common in specific applications such as heavy machinery transportation.

Handling

Pallets can be easily moved with forklifts and pallet jacks, while skids may require additional handling equipment.

When to Use Pallets and When to Use Skids?

Companies often face challenges such as low space utilization, unclear handling processes, and concerns about damage during transportation. Understanding the differences between pallets and skids can help companies optimize logistics strategies, improve loading efficiency, and reduce damage costs.

When to use pallets:

You need to enhance the strength and stability of the load. Pallets can protect goods from damage and improve transportation safety.

Your products need to be stacked or placed on shelves in the warehouse. Pallets can be neatly stacked on shelves for easy warehouse management.

You plan to use forklifts or forklifts to move.

Standardized pallet sizes make cargo handling and stacking more efficient and reduce manual operations.

Pallets are widely used in various logistics scenarios, including warehouse storage, cargo sorting, container loading, etc. In warehouses, pallets are used in conjunction with shelf systems (Pallet Racking) to achieve efficient storage and management of goods. In addition, palletized packaging (Palletize) and stretch film packaging (Pallet Wrap) can ensure the stability and safety of goods during transportation.

When to use skids:

Heavy machinery that requires minimal lifting for transportation.

You need a platform that can be easily dragged to the surface.

When storing empty skids, it is essential to save space.

Skids are widely used in transportation scenarios that require flexibility and temporary solutions due to their simple structure and low cost. For example, in the transportation of heavy goods or waterproof goods, Skids can be used as temporary support platforms to facilitate the movement and loading and unloading of goods. At the same time, it is also suitable for scenarios where pallet standardization is not required.

How to unload pallets at LTL freight terminals?

In LTL (Less Than Truckload) freight, it is crucial to unload pallets correctly. Here are some steps:

- Prepare the pallet: Make sure the goods on the pallet are stacked firmly and fixed with pallet wrap.

- Get the necessary documents: Bring the bill of lading (BOL) and other necessary documents.

- Contact the freight terminal: Contact the freight terminal in advance to confirm the time and place of unloading.

Knowing the difference between pallets and skids is essential for effective logistics management. Although both pallets and skids are used to carry goods, there are significant differences in materials, sizes, uses, etc. Pallets have been widely used in modern logistics due to their standardization, efficiency and safety. Choosing the right type of pallet can effectively improve logistics efficiency and reduce costs.

Pallets and skids each have their own advantages and disadvantages, and choosing the right tool depends on your specific needs. If you are still unsure which option is best for your business or need help with logistics solutions, consider contacting Chinadivision. Their expertise can help you effectively address warehousing challenges. As a professional third-party logistics service provider, ChinaDivision provides comprehensive logistics solutions, including palletization, packaging, transportation and warehousing management of goods.