What Is the Use of Dunnage in Transportation?

Did your goods get damaged during transportation because there was no dunnage to protect them? Originally wanted to save packaging costs, but not using dunnage resulted in low transportation efficiency and increased transportation costs? When the goods arrive at their destination damaged or damaged, the customer is dissatisfied. Any of these situations can damage a shipper or manufacturer's reputation and lead to financial losses. So how should we solve such problems?

what is Dunnage?

Dunnage refers to materials used to support and protect cargo during transportation. It serves several purposes, including securing the cargo in place, preventing movement, and protecting it from damage. Dunnage can be made from various materials, depending on the nature of the cargo and the mode of transportation.

Common types of dunnage include

1. Wooden Dunnage

Wood is a traditional material used for dunnage. Wooden blocks, boards, or shoring can be employed to secure cargo in place, create barriers between items, or provide a stable foundation for the load.

2. Air Bags

Inflatable air bags are often used to fill void spaces in shipping containers, trucks, or railcars. They provide cushioning and help prevent the movement of cargo during transit.

3. Foam Dunnage

Foam materials, such as polyethylene or polyurethane foam, are used for cushioning and protecting fragile or sensitive items. Foam dunnage can be cut to fit the shape of the cargo and provide a secure buffer against shocks and vibrations.

4. Strapping and Bracing

Straps, braces, and other restraints are forms of dunnage used to secure items in place, especially in larger shipping containers or on pallets. They help distribute the load and prevent shifting.

5. Plastic Dunnage

Plastic materials, such as molded plastic blocks or air-filled plastic bags, can be used for securing and separating cargo. They are lightweight and adaptable to various cargo shapes.

6. Cardboard or Paper Dunnage

Cardboard or paper-based materials can be used as filler or padding between items. They are often used for lightweight or less fragile cargo.

7. Steel Dunnage

Steel bracing or support structures may be used for heavy and bulky items. They provide strong support and stability, especially in situations where high strength is required.

8. Textile Dunnage

Fabric-based materials, such as straps or nets, can be used for securing and restraining cargo. They are flexible and can conform to the shape of the items being transported.

The choice of dunnage depends on factors such as the type of cargo, mode of transportation, and the potential risks during transit. Properly selected and applied dunnage helps ensure that goods arrive at their destination undamaged and in good condition.

What is the use of dunnage in transportation?

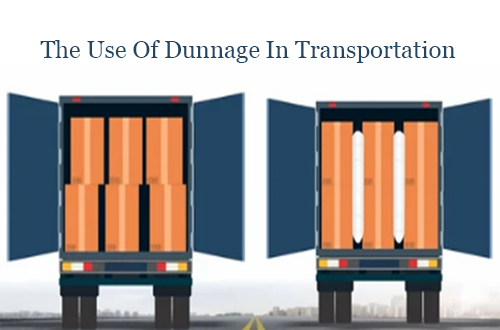

1. Cargo Stabilization

Dunnage is used to prevent the movement of cargo within a container or on a truck, ship, or railcar. This helps maintain the stability of the load during transit, reducing the risk of damage caused by shifting or sliding.

2. Protection Against Vibration and Impact

Dunnage materials such as airbags, foam, or wooden blocks absorb shocks and vibrations during transportation. This protection is crucial for fragile or sensitive goods that could be damaged by impact.

3. Air Circulation

In the case of certain goods, especially those sensitive to humidity or temperature changes, dunnage may be used to allow air circulation within the cargo space. This helps prevent moisture buildup and maintains optimal conditions for the transported goods.

4. Load Separation

Dunnage is often placed between individual items or layers of cargo to prevent them from coming into direct contact. This separation minimizes the risk of abrasion, scratching, or other forms of damage that could occur during transit.

5. Customized Packaging

Dunnage can be tailored to the specific needs of the cargo. For example, custom-shaped foam inserts can cradle delicate items, providing a secure and snug fit within the shipping container.

6. Weight Distribution

Dunnage may be strategically placed to help distribute the weight of the cargo evenly. This is particularly important for large shipments or when transporting goods that require a balanced distribution to prevent tipping or overloading in specific areas.

7. Compliance with Regulations

In some cases, dunnage is used to comply with regulations related to the transport of certain goods. For example, it may be necessary to use specific materials or methods to meet safety standards or environmental requirements.

Overall, the use of dunnage in transportation plays a crucial role in ensuring that goods reach their destination in good condition, minimizing the risk of damage, and complying with transportation regulations.

7 common types of dunnage in logistics transportation

Common types of padding in logistics transportation include paper padding, plastic padding, bubble padding, foam padding, etc. Each of these litters has its own characteristics. For example, paper litter is environmentally friendly and biodegradable, but has a weak load-bearing capacity; plastic litter has a strong load-bearing capacity, but may have a certain impact on the environment.

1. Solid materials such as wood or plastic

Solid materials such as wood or plastic are used for heavy-duty dunnage needs and are often formed into pallets, blocks or support systems to support larger, heavier items during transportation.

2. Air cushion film

Air cushion film is also a common logistics and transportation cushioning material, mainly used for shockproof buffering. It has good shock absorption, impact resistance, heat sealing properties, and is also non-toxic, odorless, moisture-proof, and corrosion-resistant.

3.Kraft paper

Kraft paper dunnage is often used for gap filling and lightweight cushioning during trucking. Not only can it be crumpled and used to fill gaps in packaging, effectively preventing items from moving during transportation, it can also be used to wrap individual items for added protection, or for Create layers of separation between different types of items.

4. Bubble wrap

Bubble wrap is commonly used to transport fragile items, with each inflated bubble acting as a miniature cushion to absorb shock and vibration that may occur during transportation without adding weight to the cargo. Minimize the risk of damage when transporting glassware, electronics or other fragile items.

5. Hard plastic or solid plastic padding

In industrial and B2B environments, if you are transporting heavy or sharp products, you will need to use rigid plastic or solid plastic dunnage that will better protect your products. You can also use molded cardboard as an eco-friendly option.

6.Bubble

Commonly used to fill electronics, medical equipment, and fragile or sharp parts by being used on the sides in boxes.

7.Steel

When shipping high-value products that are heavy, steel can be considered to prevent heavier products from damaging lighter products.

When using dunnage, you must first select a suitable dunnage type based on the nature of the goods, transportation method and environmental conditions. For fragile or sensitive cargo, it may be necessary to use foam dunnage or bubble dunnage with better shock resistance.

Secondly, the use of dunnage includes placing dunnage between goods or between goods and packaging boxes to ensure that the goods will not move, collide or be damaged during transportation.

Note that the thickness and density of dunnage should also be selected based on the weight and volume of the cargo to provide adequate support and protection.

Usage scenarios of dunnage in logistics and transportation

Cargo protection

Dunnage can be used to protect goods and reduce damage caused by bumps, vibrations and collisions during transportation. The padding can play a buffering role, dispersing the impact of external forces on the goods and ensuring that the goods remain intact during transportation.

Stable stacking

During the transportation of goods, goods often need to be stacked together. Cushions can be used to increase friction and stability between goods, prevent goods from sliding or collapsing during transportation, and ensure safe transportation of goods.

Moisture and waterproof

Some goods are very sensitive to moisture and moisture, and dunnage can prevent moisture and water. For example, using moisture-resistant dunnage can prevent cargo from getting damp, moldy or damaged. This is especially important for some electronic products, paper products and other goods that have high humidity requirements.

Fill gaps

In the transportation of goods, there may be gaps between the goods, which can lead to instability of the goods. Dunnage can be used to fill these gaps to keep goods tightly packed, reduce movement and collisions, and maintain the stability and integrity of goods.

Choosing appropriate dunnage and using and managing it according to actual needs can ensure the safety and integrity of goods during transportation.