What Role Does Milk Run Play in Logistics and Distribution?

In the global supply chain, the traditional "multi-point scattered pickup" model is trapping companies in a quagmire of soaring transportation costs and slow inventory turnover. According to DHL's "2023 Global Logistics Report", companies that adopt the Milk Run system can reduce transportation costs by 28% and reduce inventory backlogs by 35% on average.

Table of Contents

This article will deeply analyze the role of Milk Run in logistics and distribution, explore its application, advantages and disadvantages in modern logistics, and provide companies with feasible solutions.

What is Milk Run in logistics?

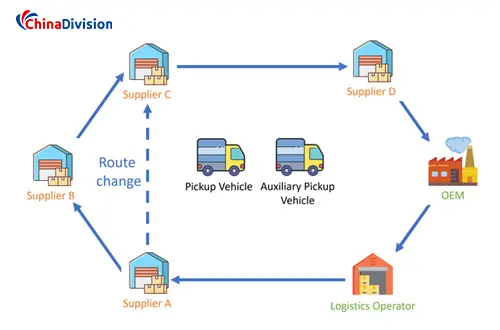

Milk Run, also known as circular pickup or collection and distribution, is derived from the classic model of collecting milk at a fixed time and fixed point in the dairy industry. It is an efficient road transportation method. Goods are collected from multiple suppliers on a regular basis through a predetermined route and time and delivered to one or more destinations. Ultimately, all collected goods will be delivered to the manufacturer's warehouse or production line. This model not only optimizes transportation costs, but also improves logistics efficiency.

Rather than having each supplier ship separately, circular pickup consolidates the goods into one shipment, thereby reducing transportation costs and improving efficiency. In addition, milk delivery can be combined with the "pallet in, pallet out" practice, where the carrier returns the empty pallet to the supplier for the next round of delivery. This not only optimizes space but also ensures the continuous flow of goods.

Application of Milk Run in modern logistics

The Milk Run model is widely used in industries such as automotive parts and home appliances. Its core value lies in the centralized management and efficient use of logistics resources by coordinating the transportation needs of multiple suppliers.

Against the backdrop of rising logistics costs and increasing inventory pressure, Milk Run has become an important tool for many companies to reduce costs and increase efficiency. According to relevant statistics, the successful implementation of Milk Run can save companies at least 10% of in-plant logistics costs and reduce 20% of out-of-plant logistics costs.

Advantages and Disadvantages of Milk Run Logistics

Advantages of Milk Run Logistics

Reduced Inventory and On-Time Arrival: Through high-frequency, small-batch pickup methods, Milk Run helps companies achieve leveled order supply and meet the timely and orderly supply of production schedules and needs. Circular pickup helps maintain effective inventory levels and prevent out-of-stock and overstocking. This is critical for companies that need to meet demand without having funds tied up in excess inventory.

Reduced Logistics Costs: Through carpooling and loading management, the loading rate of transport vehicles is increased, and the number of transport trips and waste are reduced.

Improved Logistics Efficiency: Fixed routes and schedules make logistics planning and tracking easier and improve management accuracy.

Sustainable Logistics: Carbon emissions are reduced due to the reduction in the number of transports, making it one of the most sustainable logistics models.

Faster delivery time: Faster and more predictable delivery times can be achieved due to following established routes and schedules.

Disadvantages of Milk Run Logistics

Supplier addresses need to be relatively concentrated: Dispersed supplier addresses increase transportation costs and time.

Supplier quantity control: Too many suppliers will increase the complexity of the route and may lead to poor operation. All suppliers must be ready to load at the same time, and any delay may disrupt the entire process.

Transportation risks: There may be risks in carrying multiple batches of goods on one vehicle. Problems such as traffic accidents or vehicle breakdowns may affect the entire transportation process.

How can I apply the Milk Run method to my order fulfillment process?

Supplier management

The company needs to screen and optimize the supplier network to ensure that the supplier addresses are relatively concentrated and the number of suppliers on each route is controlled within a reasonable range. At the same time, the supplier's product quality needs to remain stable to reduce operations such as returns, exchanges and replenishments.

Route planning

Using advanced logistics planning and information systems, design efficient pickup routes based on the types and quantities of raw materials and parts required by manufacturing companies and the distribution of suppliers. Use route management software to optimize pickup and delivery routes.

Consolidated freight

Instead of using different vehicles to go to different suppliers multiple times, all goods can be consolidated and shipped through circular freight, thereby improving transportation efficiency and reducing costs.

Just-in-time (JIT) inventory

Circular supply helps companies deliver goods on time when needed, thereby maintaining a lean inventory system and reducing warehousing costs.

Cross-docking operations

Goods can be picked up, shipped and transferred between various modes of transportation without storage, which speeds up the distribution process.

Information sharing

Establish an information sharing platform with suppliers to ensure that suppliers can respond to order requirements in a timely manner and organize production and delivery. At the same time, manufacturing companies can use the advanced information system of third-party logistics providers (3PL) to improve the transparency and efficiency of logistics management.

Emergency plan

Develop a comprehensive emergency plan to deal with possible abnormal problems. Through rehearsals and drills, ensure the effectiveness of the emergency plan, so as to quickly solve problems and maintain the stable operation of Milk Run.

What role does Milk Run play in logistics and distribution?

In logistics and distribution, Milk Run can not only reduce the logistics costs of enterprises and improve logistics efficiency, but also optimize inventory management and reduce capital occupation. By achieving equalization of arrivals, Milk Run helps enterprises absorb working time deviations and reduce the cost of personnel and equipment. In addition, it promotes the coordination and efficient operation of the supply chain and enhances the market competitiveness of enterprises.

How can Chinadivision help?

As a professional international order fulfillment service provider, Chinadivision provides a series of solutions for B2B enterprises and e-commerce sellers to help you optimize the Milk Run process:

Intelligent route planning

Using advanced logistics management systems, we design the optimal pickup and delivery routes according to your order requirements and supplier locations to ensure efficient transportation.

Real-time monitoring and management

Provide real-time monitoring and management tools to keep you updated with the latest developments in pickup and delivery and handle emergencies in a timely manner.

Flexible delivery options

Provide a variety of delivery options according to your business needs to ensure that the goods are delivered to the destination on time and safely.

Professional support team

The professional team will provide you with support and consultation at any time to help you solve various problems in logistics and warehousing to ensure the smooth implementation of Milk Run.

Cost optimization

By leveraging economies of scale and optimizing transportation routes, Chinadivision fulfillment agents can help you reduce transportation costs and improve overall supply chain efficiency.

Faced with many challenges in logistics and warehousing, B2B companies and e-commerce sellers need to constantly explore innovative logistics models to reduce costs and increase efficiency. Milk Run, as an efficient and economical logistics and transportation method, is gradually becoming the first choice for many companies.

As a professional international fulfillment service provider, Chinadivision has rich experience and advanced technical means to provide companies with customized Milk Run solutions. We are committed to helping companies optimize order fulfillment processes, improve logistics efficiency, and reduce costs, so as to stand out in the fierce market competition. If you have any questions or needs about the application of Milk Run in logistics, please feel free to contact us.