How to fulfill orders through fulfillment services?

|

Table of contents: When to choose 3PL fulfillment? 8 steps to fulfill orders using 3PL fulfillment |

4 types of order fulfillment

Order fulfillment, as the name suggests, refers to the process by which a company handles sales orders according to customer requirements. This can be achieved by choosing a third-party logistics company to handle the entire process, handling it in-house, or a combination of both. This is a crucial aspect of a company's operations. Order fulfillment typically occurs at one or more distribution centers and involves various processes, including inventory management, supply chain management, order processing, quality control, and after-sales services, such as returns and exchanges. Today, customers have higher expectations than ever before; they crave more information and have greater rights. Efficient order fulfillment is key to maintaining brand reputation, increasing company profits, and sustaining customer relationships.

Order Fulfillment Methods:

-

In-house

This model means that all steps of order fulfillment are completed within the company. This implies that the seller has full responsibility for every aspect of order processing—from product warehousing and packaging to final delivery to the customer. This model allows companies to have complete control over the supply chain, eliminating reliance on external logistics providers. All processes are completed internally, whether in offices, warehouses, owned facilities, or leased spaces. For companies with specific needs or those requiring autonomy in their processes, in-house logistics is often the preferred option, ensuring that supply chain management fully complies with the company's own standards.

-

3PL fulfillment

This model refers to transferring all or part of the logistics process to external suppliers. In this model, once an order enters the operator's system, picking, packing, and shipping are completed automatically. Customers only see the result—the timely delivery of the order and its status notifications. This model is gradually becoming a common choice for various types of businesses.

-

Drop shipping

Orders are produced and shipped by the manufacturer. On the plus side, this lowers the barrier to entry and minimizes operating costs, which is crucial for startups and e-commerce companies. It also eliminates intermediaries, potentially saving money for buyers. On the downside, it can also deprive merchants of control, especially in inventory management and order fulfillment. Furthermore, since many manufacturers are located in other countries, far from the merchant's customer base, shipping can be significantly delayed. In this case, transportation may take longer and be more expensive, or a distribution center may need to be established to ship from there.

-

Hybridization

A hybrid model refers to combining two or more of the three models mentioned above. For example, a company might choose to handle all or part of the order fulfillment for popular products in-house, but outsource order fulfillment during peak periods such as holidays and ship large, bulky goods directly from the manufacturer.

When to choose 3PL fulfillment?

Rapid Growth Phase

When your business grows so fast that your current warehouse operations become inefficient, you employ too many staff, or your inventory management becomes difficult to track.

Demand Expansion Phase

If you are expanding your product line, opening new sales channels (such as migrating from Shopify to Amazon), or entering new sales markets, 3PL can provide the necessary capacity and infrastructure to support this growth.

Rising Costs

When partnering with a third-party logistics (3PL) provider is more cost-effective than investing in your own warehousing space, transportation assets, and technology, choosing a 3PL can help you save on fixed costs, equipment expenses, and the costs of hiring and managing logistics personnel.

Resource Scarcity

If your company lacks sufficient funds or resources to invest in building and managing its own distribution centers and transportation network, you may also need to choose a 3PL.

Special demand periods

When your products require special handling, such as refrigeration, or the transportation of hazardous materials or large items, you need a third-party logistics (3PL) company with the relevant certifications and expertise compared to other fulfillment models.

Efficiency improvement periods

When other logistics models consume your manpower, resources, and energy, 3PL can improve efficiency by managing complex processes such as order fulfillment, inventory tracking, and global logistics, allowing your business to focus on its core competencies.

Seasonal sales fluctuations

When dealing with seasonal sales fluctuations, choosing other logistics models may require additional manpower or additional space rentals to handle such sales changes. In this case, you can choose a third-party logistics company to handle seasonal demand fluctuations without worrying about overtime costs or additional staffing.

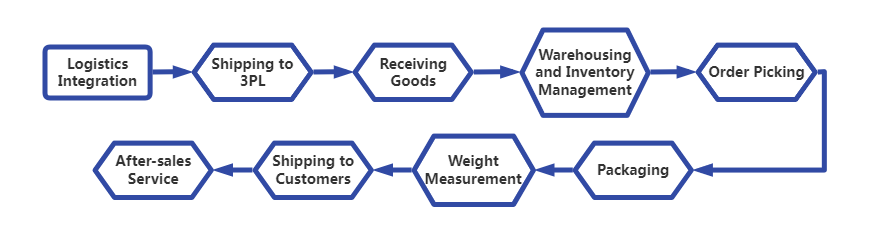

8 steps to fulfill orders using 3PL fulfillment

Logistics Integration

When you decide to partner with a professional and reliable third-party logistics (3PL) service provider like ChinaDivision, you need to understand their basic processes beforehand, identify your key concerns, and provide your logistics provider with essential order information, such as inventory and order details, so your 3PL partner can always know which products are in stock and which can be shipped. Many merchants allow their 3PL partners access to and use the necessary functions in their inventory and order software for order fulfillment. Other merchants may allow fulfillment companies to connect and synchronize order information with their third-party logistics management systems via API. Whichever method you choose, ensure that you and your third-party logistics company are both aware of every inventory update or change. This allows them to make timely adjustments and smoothly provide end-to-end logistics services for your business.

Shipping to 3PL

Goods may originate from third parties, other departments within the company, or company warehouses; pipelines (such as oil, fuel, water, or other fluid products); digital data in a database; or from various other external or internal sources. Regardless, you will need to send your inventory to a third-party logistics (3PL) warehouse so they can begin processing your orders. When shipping from a 3PL warehouse, you should consider freight costs, especially when handling large orders. Full truckload (FTL) and less-than-truckload (LTL) shipping are two cost-effective freight services that streamline the product delivery process and help you get your products to your customers. If your products are large, such as beds or motorcycles, you might consider using residential less-than-truckload (LTL) shipping services. To help you choose the right type, third-party logistics companies will provide comprehensive guidance and may even recommend the best freight options and suitable logistics services based on your needs.

Receiving Goods

refers to receiving and storing incoming inventory at a logistics center. If your brand fulfills orders itself, you are responsible for receiving and storing inventory delivered by suppliers or manufacturers. When you outsource your business to a third-party logistics (3PL) provider, they handle everything for you. Each 3PL provider has its own inventory receiving and storage process, typically requiring merchants to submit relevant documentation. This helps keep the process organized and timely, meaning your orders can begin shipping much faster. Once the goods arrive at the loading/unloading terminal, all arriving inventory must be counted, inspected, and registered to ensure the received quantity is correct and the quality is up to standard. The SKU or barcode on the arriving products is used in the receiving and storage process, and also for subsequent retrieval of goods from the internal warehouse. The goods are then stored in designated warehouse storage locations, such as shelves, boxes, or pallets.

Warehousing and Inventory Management

Third-party logistics companies, with their innovative retail management software and strategic planning expertise, can design and operate efficient, secure, and well-organized storage environments for your products. Once goods arrive at the logistics center, they may be immediately shipped or sent to short- or long-term warehouses, where they ensure that every storage box, aisle, shelf, and rack within the warehouse is closely monitored and efficiently managed. Therefore, you can maximize cargo safety, reduce costs, and achieve maximum profits.

Order Picking

Professional third-party fulfillment providers (3PLs) have their own order processing management systems. When your customer places an order, 3PL warehouse staff receive a fulfillment request notification and begin picking by batch, region, or wave. In online marketplaces, order management software can integrate with the shopping cart of an e-commerce website, automatically initiating the order processing flow. Picking teams or automated warehouse robots pick items from the warehouse according to the instructions on the packing list. The packing list contains specific information such as a list of product SKUs, product colors, sizes, quantities, and their location in the distribution center warehouse. In addition, your outsourced logistics partner will update the order status in the management system. This allows you to monitor the entire process in real time and make timely adjustments as needed.

Packaging

Packaging refers to clearly labeling product packaging with necessary information such as brand name, order number, shipping information, and shipping labels. Packaging materials are selected by the packaging team or automated picking robots to achieve the lowest possible volume and weight, thereby reducing transportation costs. If an order is lost, meticulous packaging can save time and effort in tracking and resolving the issue. Outsourcing this process to a third-party logistics (3PL) company can save you time researching optimal packaging materials and shipping box dimensions. Additionally, the packaging team usually includes return packaging materials and labels in case customers later want to exchange or return the goods for a refund.

Weight Measurement

After packaging is complete, the 3PL company will perform weight measurements. These measurements include weighing the product, pallets, skateboards, packaging film, strapping, and all other items used in the shipment. The 3PL company will determine the dimensions of the goods based on their length, width, and height to optimize its logistics and delivery process. Accurate weight measurement also improves the efficiency of the returns process because it shows whether returned products have been correctly counted in inventory. Therefore, you can be confident in the accuracy of inventory levels and avoid discrepancies in recording.

Shipping to Customers

After pre-shipment preparations are complete, the third-party logistics (3PL) fulfillment service will determine the most suitable carrier and shipping method for each order based on factors such as package weight, destination, delivery speed, and cost. Reputable 3PL service providers typically work with multiple carriers, offering you and your customers flexible shipping options. Furthermore, 3PL's logistics tracking system provides you and your customers with real-time tracking information, allowing you to monitor the entire transit process from the warehouse to your customer's doorstep. It's worth noting that freight companies, airlines, FedEx, UPS, the United States Postal Service (USPS), and other carriers all determine shipping costs based on the greater of the package's actual weight or volumetric weight. Even if the item's actual weight is very light, such as a T-shirt, it's generally worthwhile to use the smallest possible packaging method to avoid significantly increasing the package's total weight. In addition, most carriers have packaging regulations to maximize the use of available shipping space and achieve maximum profit. Failure to meet these requirements may result in the carrier refusing to accept the order, leading to shipping delays.

After-sales Service

If your customer returns an order and requests a refund, the returned goods will be delivered to a third-party logistics (3PL) warehouse. The 3PL team will carefully inspect the goods to ensure they meet the conditions for restocking, such as being free of damage, malfunctions, stains, etc. Return processing includes quality control checks and sorting of returned products. The returned products will then be processed according to your rules, such as being restocked, returned to the supplier or manufacturer to obtain a distributor refund or credit, or sent to a recycling center.

What are the advantages of using 3PL fulfillment?

-

Expanding Warehousing Coverage

Having multiple warehouses and shipping points covering the entire market is crucial. This allows you to distribute your inventory, ensuring timely delivery to buyers regardless of their location. This has two main benefits: First, the closer the goods are to the buyer, the shorter the transit time, the faster the delivery, and the higher the customer satisfaction. Second, the closer the items are to their destination, the lower the shipping costs, thus generating more revenue for your business. For individual businesses, purchasing warehouses around the world is impractical. However, by partnering with a third-party logistics provider, you can leverage their warehousing network and simply pay for the storage space and locations you need.

-

Reducing Operating Costs

Businesses typically reduce operating costs by outsourcing logistics. These processes are time-consuming and labor-intensive, incurring additional labor costs in addition to service fees. By having a third-party logistics (3PL) provider handle logistics, businesses can eliminate these labor costs. Outsourcing transportation logistics can also reduce fleet maintenance costs, leading to savings on fuel and maintenance expenses.

-

Enhancing Logistics Flexibility

By outsourcing logistics management to a professional logistics service provider, your company can quickly and efficiently adapt to demand fluctuations and market changes, flexibly handling orders ranging from small to large batches. Simultaneously, the responsiveness of your supply chain will become a competitive advantage, enabling your company not only to flexibly respond to market pressures but also to support continued growth and expansion. In short, logistics outsourcing not only allows you to effectively address current needs but also helps you anticipate and seize future opportunities.

-

Focusing on Core Operations

Outsourcing logistics allows companies to focus on their core business operations, avoiding the creation of additional logistics tasks and positions that could consume valuable time and resources and hinder core business development. Many companies choose to outsource logistics to rid themselves of labor-intensive tasks that are not part of their core competencies. By entrusting these tasks to companies that specialize in specific parts of the supply chain management (such as transportation or warehousing), you can focus on critical production-related tasks that contribute to business growth.

-

Improving Customer Satisfaction

Professional logistics companies offer reliable delivery times and reasonable shipping costs. Furthermore, customer service will handle any issues promptly and efficiently during transit, all of which helps businesses enhance customer service and the overall experience. Creating a positive first impression is crucial after a customer's initial purchase, and outsourcing logistics helps ensure efficient order management, thereby improving the customer experience.

Conclusion

Partnering with a professional, reliable, and reputable third-party logistics (3PL) provider can bring scalability, cost savings, and expertise to your business, helping you thrive in a competitive market. Whether you want to deliver products directly to end users, Amazon warehouses, or large retailers, the right 3PL partner can help you deliver a seamless customer experience and turn logistics into a competitive advantage.

ChinaDivision's Logistics Integration Plugin provides a simple, free, and powerful solution to streamline your order fulfillment process, seamlessly connect to your e-commerce platform, and enable real-time inventory tracking and automated order processing. We are constantly evolving to adapt to the trends in modern online e-commerce, helping you stay ahead of the curve and competitive edge.

FAQs

1、Can my customers get an email notification of my shipment's progress or status?

Upon shipping your order, the dashboard will pass the shipped status along with a related tracking number (if applicable) to your CRM. Depending on the capabilities of your CRM or E-Commerce platform, a "Shipped" confirmation email may be generated by your CRM/E-Commerce platform and sent to the consumer.

2、What does it mean if I see "billing information received" or "electronic shipping information received"?

If you see either of these two shipping messages, the shipping company has received your information and tracking number, but your package has not been scanned in their facility yet. Wait a day or two and see if the problem resolves itself.

3、How do we need to notify ChinaDivision when we are sending our inventory to one of the ChinaDivision warehouses?

Send an ASN (Advanced Shipping Notice). It will inform the ChinaDivision of how many units we will be receiving from your supplier. An ASN is electronic information concerning a single shipment of movable units sent to a WMS from suppliers and sent from a WMS to customers. If you do not have this capability, please contact your sales manager for further information.

Reference:

1、What Is Order Fulfillment? 7 Step Process & Key Strategies

https://www.netsuite.com/portal/resource/articles/erp/order-fulfillment.shtml